Metallurgy

Metallurgy includes all stages of metal processing, from the raw state (created from the ore) to its final form. During this process, the metal will be melted, shaped, treated, welded, coated and sometimes painted. This variety of transformations can be risky, with unforeseen splashes of different magnitudes. These splashes are sometimes microscopic, difficult to spot and therefore complicated to wash off later if the exposed employee does not realize it. In addition, the phenomenon of oxidation of liquid steel baths also represents a danger.

This industry uses a wide variety of corrosive and sometimes toxic chemicals, such as hydrofluoric acid (HF) in large quantities to modify the characteristics or appearance of metals.

The risk of contact with the numerous chemicals used during the various stages remains non-negligible for workers.

The employee needs to have an effective rinsing solution against all irritating or corrosive chemicals and an effective solution against hydrofluoric acid (HF).

Advantages of the Diphoterine® solution for this sector

- Wash anywhere

- Quick intervention

- Unique protocol

- Fast and serene reaction

- Soothes the pain

- An effective solution against all types of chemical substances

- A reliable wash for any injuries

- The Hexafluorine® solution for the handling of HF splashes

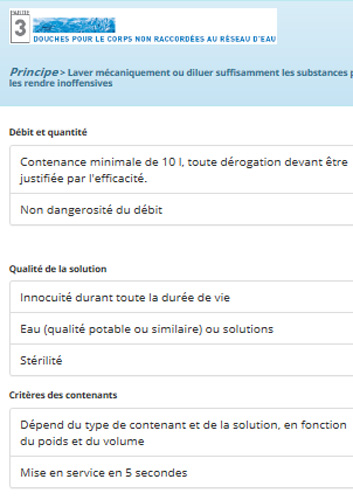

Mobile solutions

Individual containers

Collective containers

Testimonials

Read our studies on solutions