Paper Industry

We can identify three main pulp manufacturing processes and all of them pose a chemical risk. In addition, chemicals are found in support activities: Laboratories, water treatment (a lot of water is used during production) and storage.

- Mechanical process: It is mainly used to produce paper for newspapers and magazines.

a. Bleaching: Use of chlorine dioxide, ozone or hydrogen peroxide, sodium hydrosulfite, caustic acids, bases and solvents in this operation.

b. Maintenance: Cleaning operations on pipes, valves, hoses and tanks are carried out using cleaning products (caustic and sulphuric acid). In addition, there are hydrofluoric acid pickling pastes for the maintenance of welds on stainless steel. - Chemical process :

a. Digester: The process in which wood fibres are isolated using chemicals.

– Alkaline process: with caustic soda or sulphate.

– Acid process: with bisulfite.

b. Bleaching and maintenance - Recycling process: pulp is made from waste paper.

a. Hot dispersion: This process can be accompanied by chemical treatment (hydrogen peroxide, sulfonic acid and sodium hydrosulfite)

b. De-inking: Removing ink particles from printed materials. Hydrosulfite, sodium silicate, greasy acids or soaps are used to facilitate separation.

In industries where the risk of chemical splashes is common, it is necessary to be able to offer efficient and fast rinsing solutions to employees. In addition, a suitable product is needed to counter the corrosive and aggressive aspects of certain chemical substances, such as hydrofluoric acid (HF).

Advantages of the Diphoterine® solution for this sector

- Wash anywhere

- Quick intervention

- Unique protocol

- Fast and serene reaction

- Soothes the pain

- An effective solution against all types of chemical substances

- A reliable wash for any injuries

- The Hexafluorine® solution for the handling of HF splashes”

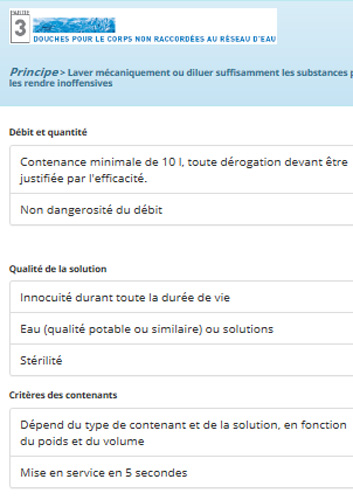

Mobile solutions

Individual containers

Collective containers

Testimonials

Read our studies on solutions